Solid Value. Solid Terms. Solid Logistics.

Solid Value

With Keg River’s premium fertilizers, every dollar spent on sulfur provides a return on investment in the field. Superior degradability ensures that our fertilizers are fully utilized by crops, and are not being tied up in the soil.

Solid Terms

Keg River provides corporate buyers and retail buyer groups with competitive programs and tiered volume incentives that align with their business objectives. We have a proven reputation for delivering on our contracts and meeting our commitments. We don’t disappear after an order has been delivered.

Solid Logistics

Keg River is committed to making sure you receive the products you ordered in a timely manner. We employ best logistical practices to ensure efficient delivery of our fertilizers by rail and through our dedicated trucking team.

We Deliver. On Our Products. And On Our Promises.

The entire team at Keg River is committed to your success and satisfaction as a customer. We will work to resolve any issues in a fair and equitable manner.

We work with multiple suppliers, each selected for their ability to meet our uncompromisingly high product specifications. By not putting all of our eggs in one basket, we are able to avoid unanticipated supply shortages and honour our commitments.

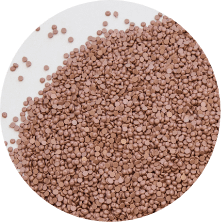

North America’s most trusted elemental sulfur fertilizer.

Keg River supplies our premium bentonite sulfur fertilizers to North America’s largest line suppliers and an extensive network of independent retailers – across the Western USA and Midwest, Western Canada and Quebec.

Our Facilities

All products are made at our manufacturing plant in Edmonton, Alberta, Canada. Our average daily production is 410 ST (370 MT) per day. Construction is underway on our dedicated organic manufacturing facility on the same site, to be completed in 2021.

We’ve refined our manufacturing processes to maintain the highest degree of consistency, and take great care to maintain our equipment to the highest operating standards.

For our drivers and customers, time is money. Our covered, all-weather loading platforms are built with weigh scales to ensure greater loading efficiency and allow us to provide accurate shipping documentation. Our silos are on load cells, for greater accuracy. We process 25 loads per day (seasonal average), getting trucks promptly in and out — so we aren’t eating into log hours.

Batch Tracking for Enhanced Accountability and Quality Control.

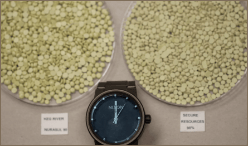

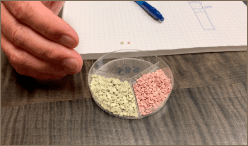

We are sticklers for quality control. Before a shipment goes out of our doors, we collect batch samples and measure for fine and fractured particulate levels. We track our product by the shift and by the load (samples are taken from a truck after loading). We retain samples for further testing. This provides a baseline to ensure proper product handling at every stage of the shipping process.

As part of our testing process, we conduct degradability testing and burn tests to verify each product meets Keg River’s high standards for quality.